|

|

Operations Management is a vital component of any business, encompassing the practices, techniques, and tools that organizations use to produce and deliver goods and services efficiently and effectively. Whether in manufacturing or service industries, operations management plays a crucial role in building a competitive edge and driving long-term success. In this article, we will talk about What Operations Management is, the benefits of Operation Management, how to become an Operation Manager and More.

Table of Content

What is Operations Management?The creation, supervision, and control of the systems and procedures that businesses utilize to generate commodities and provide services are the main objectives of the management field known as Operations Management. To guarantee the effective and efficient production of goods or the provision of services, it involves the planning, organizing, and optimization of resources, processes, and activities. In several sectors, including manufacturing, healthcare, retail, transportation, and services, operations management is essential leading to enhanced customer happiness, cost savings, and efficiency.

Importance of Operations ManagementOperations form the backbone of any company, focussing its approach to managing the supply chain and logistics intricacies. The financial health of a business is deeply tied to its ability to maintain lean and effective operational strategies. Inadequate operational practices pose a significant risk to a company’s longevity, highlighting the necessity for process optimization. Employing proficient staff, ensuring operations are ethical and safe, and choosing strategic locations are important for maintaining operational excellence. This not only enhances efficiency but also supports the organization’s commitment to ethical practices and safety standards, crucial for sustainable growth and customer trust. Purpose of Operations Management

What does an Operations Manager do?Here are some of the tasks done by Operations Manager:

How to Become an Operations Manager?In order to become an Operations Manager, the below listed qualifications are required: 1. Educational Background: A bachelor’s degree in business administration, engineering, supply chain management, operations management, or a similar discipline is often held by operations managers. A master’s or MBA may be pursued by some people to advance in their careers. 2. Acquire Useful Work Experience: Get practical experience in operations management-related fields. A basis for understanding operational procedures can be obtained through entry-level positions in industries such as production, logistics, or quality control. 3. Develop your Technical Abilities: Get technical expertise in areas related to operations management. Proficiency with enterprise resource planning (ERP) systems, data analysis software, project management tools, and other operational technology may be required. 4. Developing your Communication and Leadership Skills: Managers of operations often supervise teams and work with different departments. Success in operations management is largely dependent on effective leadership and communication. 5. Attain Expert Certifications: Think about earning the necessary credentials. You can improve your credentials with certifications like Project Management Professional (PMP), Certified Supply Chain Professional (CSCP) or Certified in Production and Inventory Management (CPIM). 6. Show Off your Problem-Solving Skills: Display your ability to solve problems. The difficulties and inefficiencies in operational procedures must be addressed by operations managers. In your past employment, highlight the times you detected and resolved problems effectively. 7. Seek Guidance: Seek guidance from seasoned operations managers or other business experts. As you advance in your job, a mentor can offer direction, wisdom, and counsel. Skills Required to Become Operational ManagerThe skills required from an Operations Manager are:

Career Paths in Operations ManagementHere are some of the Career Paths in Operations Management:

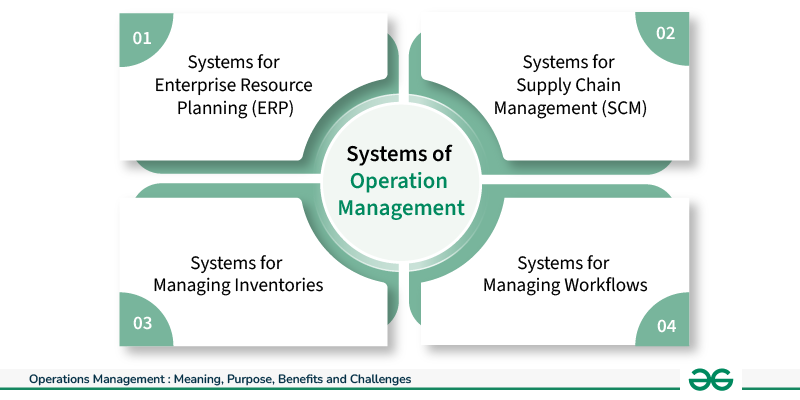

Systems of Operation ManagementThe Systems on which Operation Managers work are: 1. Systems for Enterprise Resource Planning (ERP): ERP systems combine several corporate operations, such as supply chain management, manufacturing, finance, and human resources. To support real-time information sharing and decision-making throughout the company, they offer a centralized database and a suite of applications. 2. Systems for Supply Chain Management (SCM): From the acquisition of raw materials to the delivery of completed goods, supply chain management (SCM) systems assist businesses in managing the whole supply chain. These technologies increase overall logistics and distribution efficiency, optimize inventory levels, and strengthen supplier relationships. 3. Systems for Managing Inventories: By giving businesses real-time visibility into stock levels, demand projections, and order fulfillment, these technologies assist businesses in optimizing their inventory levels. Their objectives are to lower holding costs, avoid stockouts, and boost overall inventory effectiveness. 4. Systems for Managing Workflows: Systems for managing workflows make it easier for different operations and activities to be automated and coordinated inside a company. They ensure that tasks are carried out methodically and effectively, help to streamline procedures, and minimize the need for manual intervention. Challenges of Operations ManagementHere are some the challenges faced by Operation Managers: 1. Globalization and Complex Supply Networks: The complexity and interconnectivity of supply chains have increased with the globalization of business. Coordination, communication, and cultural variations become obstacles when managing suppliers, logistics, and production processes across borders and time zones. 2. Demand Variability and Forecasting: Demand can be difficult to predict accurately, and changes in consumer demand might result in overstock or stockouts. To adapt to shifting demand patterns, operations managers need to create flexible production procedures and efficient forecasting models. 3. Skill Shortages and Talent Management: One of the ongoing challenges in operations management is finding, developing, and keeping competent employees. Technology’s constant evolution combined with greater rivalry for talent may result in a lack of skilled workers, which will reduce operational efficiency. 4. Assurance and Control of Quality: It is difficult to consistently provide high-quality goods or services. Vigilant monitoring and ongoing improvement initiatives are necessary due to variations in supplier quality, production process variability, and adherence to quality standards. Benefits of Operations ManagementHere are some of the Benefits of Operations Management:

Examples of Operations ManagementSome Examples of Operations Management are:

SummaryIn conclusion, Operations Management is not just a department or a function within an organization; it is a thorough approach that requires a holistic view of the organization’s objectives and strategic goals. However, managing operations isn’t always easy. Companies face challenges like managing their supply chains, keeping up with new technology, maintaining quality, and adapting to changes. It’s about finding the best ways to create and deliver products or services. Operations Management – FAQsWhat makes Operations Management critical?

What are Operations Management’s core elements?

How can operational efficiency be increased?

What difficulties do Operations Manager face?

What are the 3 types of operations management?

|

Reffered: https://www.geeksforgeeks.org

| Commerce |

Type: | Geek |

Category: | Coding |

Sub Category: | Tutorial |

Uploaded by: | Admin |

Views: | 14 |