|

A single-phase induction motor is an electric motor that functions using single phase power supply system. Single phase induction motors are relatively easy to build, are rather robust in their construction, and are commonly applied in households, offices, shops, small industries etc This article explains how single phase induction motors work, how they are classified and how they are used in practice.

What is a Single Phase Induction Motor?

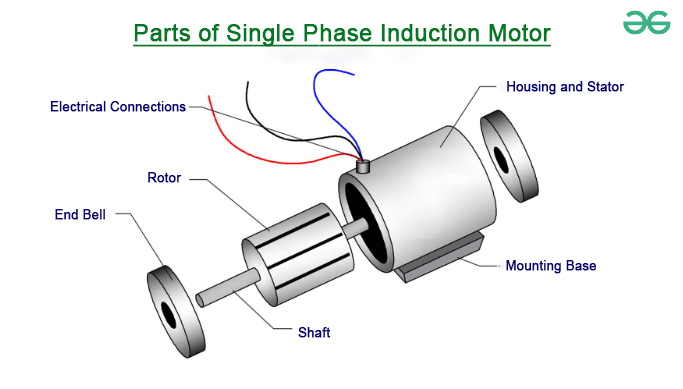

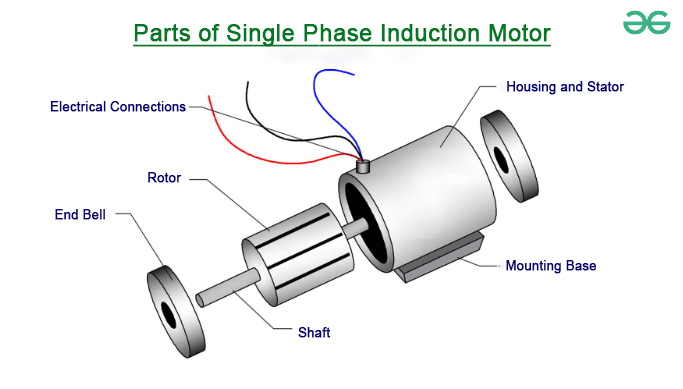

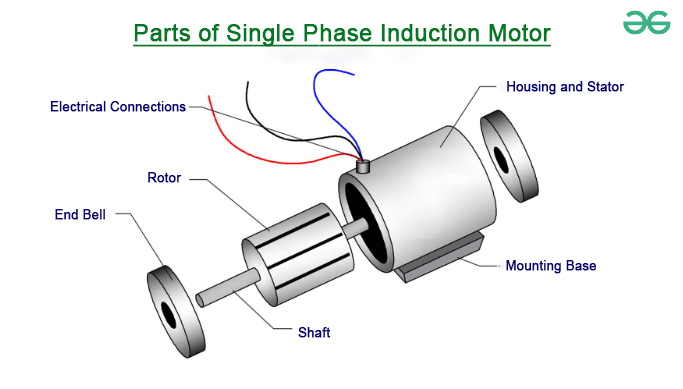

A single phase induction motor comprises of one phase winding which is located in the stator and a rotor which is made up of a squirrel cage. In this case, when the stator is connected to a single phase AC supply, a pulsating magnetic field is established in the stator of the motor, which in turn induces currents in the rotor of the motor. These rotor currents interact with the stator magnetic field to result in the torque and hence rotation. Single phase induction motors can be classified on the basis of winding connection and rotation of the magnetic field they develop.

Working Principle

A single-phase induction motor essentially uses the same methodology of magnetic induction between the stator and the rotor as any other induction motor on the market. Here is a quick overview of how a single-phase induction motor works:

- Stator: The rotor is formed of a single coil (main coil) supplied by a single phase AC voltage source, the stator. It generates a magnetic field that goes through a rotational movement within the motor.

- Rotor: The stator and the rotor of the given motor are also of squirrel cage type as seen in other induction motors. The unique designs of the conductor bars are shorted by end rings.

- Auxiliary Winding: It also has an auxiliary/starting winding in addition to the main or complete winding of the stator. This winding is physically shifted by 90 degrees to the main winding and can also have different resistance. Both windings are energized when the motor begins to operate..

- Starting: When energised, the magnetic field of each winding rotates in a plane that is perpendicular to the other winding’s magnetic fields. This field creates a circuit in the rotor bars and makes the rotor to start revolving. After it reaches near the synchronous speed, the auxillary winding is taken out of circuit.

- Running: With the increasing rotor speed, the direct interaction of the magnetic fields of the rotor and the rotating stator field gives rises to additional rotor current and torque. This brings the rotor nearer the synchronous speed thereby accelerating it forward. The rotor which is not provided any direct supply of power gets its power transferred to it through induction in order to be able, perform useful work.

Applications of Single Phase Induction Motor

Some major applications of single phase induction motors include:

- Fans: Single phase induction motors are used in majority of fans for air ventilation, exhaust and cooling etc, the motor drive fans used in home appliances such as table fans, pedestal fans, exhaust fans. They are also included in industrial cooling fans, ventilators, and so on.

- Pumps: These motors are used in driving pumps for transferring liquids in various tasks such as; water pumps, centrifugal pump, circulation pump in home appliances and industries. Some examples of these applications are water transfer pumps, swimming pool pumps, etc.

- Home Appliances: They are widely used in home appliances such as washing machines, air conditioners, refrigerators, mixers, etc. where they are used in starting the compressor, agitators and various types of rotating components.

- Office/Business Equipment: Single phase induction motors generally powers business machines such as conveyors, packaging machines, blowers, office appliances, vending machines, etc.

- Power Tools: Several power tools employed in production lines, construction companies employ a single-phase AC motor because of their superior start torque. Some examples include drills, vacuum cleaners, and the like.

- Servomotors: In the automation industry, single phase servomotors are used for offering a variety of speed and position feedback.

Advantages of of Single Phase Induction Motor

- Simple and rugged construction: Single-phase induction motors have a basic structure with stator that rotates a rotor and only a single winding. This makes them rigid and strong thus making them hard wearing.

- No need for starting device: These motors are self starting motors and therefore will not need any other starting equipment. This is because it brings down the total costand simplifies the process.

- Low cost: Single phase motors are affordable as compared to three-phase motors having the same amount of the output power. This makes them suitable for different uses as they can be bought at a cheap price.

- Low maintenance: These motors are very reliable due to their simplicity of construction and the fact that they have very few wearing parts thus negligible maintenance costs. It might not be necessary to use the product very often in order to maintain a smooth and slippery surface.

- Versatile operation: It is important to note that these motors have good starting torque and would be ideal for operating various types of light industry and household equipment. They can also be utilized with single phase power supply systems.

- Quiet operation: Single phase induction motors are also ideal because the motors run quietly without any vibrations or noisy sounds. This makes them ideal for use where noise is a problem.

- Variety of sizes available: These motors are manufactured in all sizes from fractional horsepower motors to motors with higher horsepower rating. Size can be selected based on need, that is, small, medium or large can be chosen.

Disadvantages of Single Phase Induction Motor

- Fluctuating speed: Single phase motors operate at low efficiency and often exhibit fluctuating speed, which is not ideal for the majority of applications. This leads to problems in starting bigger loads in one go.

- Non-synchronous: Single phase motors are non-synchronous and require an extra winding known as auxiliary winding and Centrifugal switch to start. This adds mechanical complexity.

- Lack of smooth running operation: Due to the pulsating torque characteristic, single phase motors tend to cog or vibrate back and forth slightly, during operation. This is an inherent issue that can be attributed to many factors, but the most significant of these are the psychological problems that are often associated with suicidal ideation.

- Slowing down mechanism: Control of speed in single phase motors cannot be as simple and effective as in 3-phase motors; for instance, speed control through pole changing or voltage alteration is complicated.

- More expensive: Generally, single phase motor costs are higher than those of the 3-phase motors of the same size and capacity due to the extra components used.

- Restricted distances: The practical restriction of single phase motor design prevent very large horsepower rating. Single phase motors available in the market are mostly not above 10 horsepower and are the largest.

Future Trends

- For single phase induction motors, development of speed control methods that can enable the motors to operate at variable speeds without having to incorporate sensors.

- Controlling design factors and parameters for improvement of efficiency with reduced size/weight.

- Motor that is connected with communication abilities and digital control integrated into its design.

Conclusion

The single phase induction motors are used very widely in fans, blowers, pumps, home appliances, small machine tools, etc because of their simple construction, low cost of manufacture and they have built in self starting capability. Despite their shortcomings, these motors will remain useful particularly for their efficiency and the ongoing research aiming at solving other issues concerning speed control.

Frequently Asked Questions on Applications of Single Phase Induction Motor – FAQ’s

What is the purpose of single phase induction motors and the areas where they are most often used?

Single phase induction motors find their applications in residential an commercial places including fans, blowers, centrifugal pumps, washing machines, grinder and many more which do not need speed control.

Which type of motors are used in domestic as well as commercial applications where light loads are involved?

Single phase induction motors are used extensively in household and commercial places due to their simplicity and robust construction, low cost, low maintenance and the ability to run on a single phase power supply which is readily available in most residential and commercial establishments.

Can single phase induction motors be used for industrial purposes where the horsepower is little higher?

The single phase induction motor is typically a low horsepower motor, there are slight modifications which are the capacitor motors and the repulsion start motors which enable the single phase induction motors to have high horsepower ratings. Therefore, they are applied for some industrial uses like conveyors, pump, compressors etc But for heavy load of industries such as high starting torque and high horsepower devices, the 3-phase induction motor is more appropriate.

|